Hair Tips

Wholesale Wavy Hair Extensions from Vietnam: What Buyers Should Know

Wholesale buyers increasingly source wavy hair extensions from Vietnam. They look for stable quality, factory control, and long-term supply. Wavy textures demand even higher consistency than straight hair.

This article draws from hands-on production experience at Lexhair Factory, a Vietnam-based manufacturer supplying wavy hair extensions to salon and wholesale partners worldwide. The goal is simple. Help buyers understand what truly matters before placing bulk orders.

Global demand for hair extensions continues to rise. Industry reports from organizations such as Grand View Research show steady growth driven by salons and professional users. As volume grows, sourcing decisions become more critical.

Why Vietnam has become a key source for wholesale wavy hair extensions

Vietnam offers a strong manufacturing base for human hair products. Many factories manage sorting, processing, and finishing in one location. This structure helps maintain consistency across large orders.

Trade data also shows Vietnam as an active exporter of human hair materials. Buyers often choose Vietnam for its balance of quality control and scalable production. Reliable logistics and export experience further support wholesale operations.

For wavy hair extensions, factory control matters more than origin alone. Texture stability depends on how teams handle hair during each step.

Factory supply versus trading supply: What buyers should understand

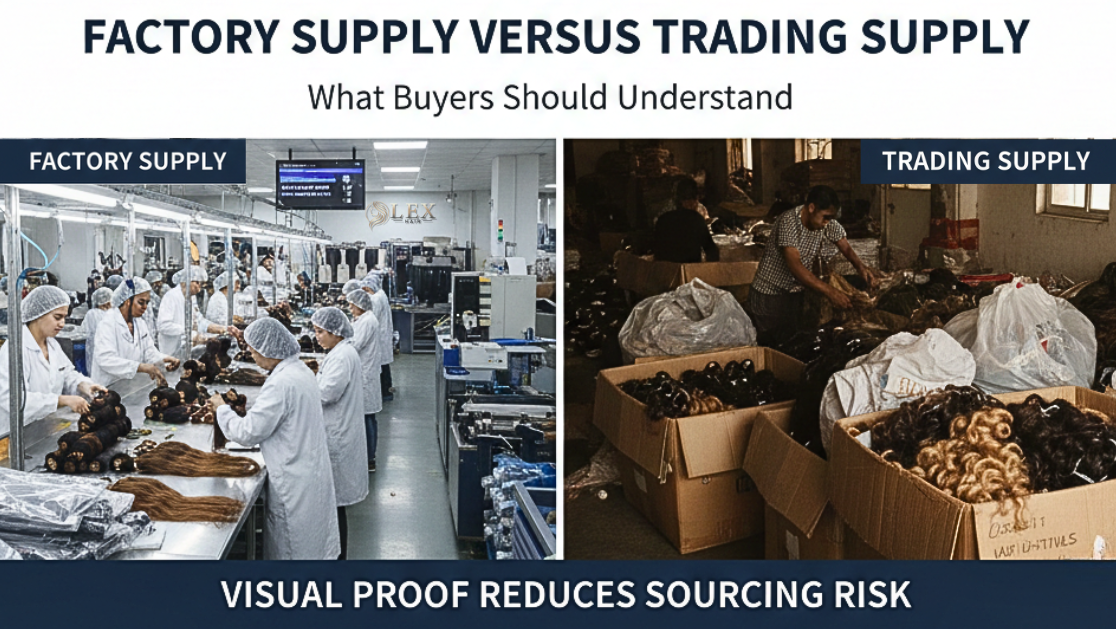

A factory controls daily production. It can repeat the same specifications across multiple batches. Traders often collect hair from different sources over time. This practice increases variation in wave shape and strand feel.

Wholesale buyers should confirm who manages the production process. A real factory can show current workflow, quality checks, and packing stages. Visual proof reduces sourcing risk.

This difference becomes clear with wavy hair. Small handling changes can alter the final texture.

Why wavy hair extensions require tighter quality control

Wavy hair reacts strongly to moisture, friction, and heat. Poor handling can loosen waves or create uneven patterns. Buyers should look beyond first impressions.

Hair science supports this concern. Research on hair fibers shows that curved strands tangle more easily under wet conditions. Surface damage increases friction and snagging. These factors affect daily salon use and client satisfaction.

Studies on hair cuticle direction and friction also explain why consistent processing matters. When factories align strands and protect cuticles, hair moves more smoothly during styling. These findings support strict quality checks for wavy textures.

What wholesale buyers should check before they order

Wave consistency across bundles

Request photos under the same lighting. Ask for dry and slightly misted views. Compare bundles side by side.

Strand feel and surface condition

Run a simple comb test. Do it from ends to mid-length. Then do it from mid-length to roots. Smooth movement suggests lower friction.

Length accuracy and end thickness

Wholesale buyers often lose money on thin ends. Ask for a clear “ends profile” photo. Ask for bundle weight standards too.

Weft integrity and shedding risk

If you buy weft products, inspect weft edges closely. Look for tight stitching and clean tracks. Ask how the team reduces short hairs near the seam.

Color and tone stability

Wavy textures show tone shifts fast. Ask for a consistent tone standard. Ask for the same lighting for all checks.

You can keep this section short on your website. Your factory images can carry the proof.

Order terms that protect wholesale buyers

Many disputes start from unclear terms. You can prevent them with simple checkpoints.

Keep these items in writing:

- Spec sheet for texture, length, and color

- QC photos or a short video before shipping

- Packaging rules for bulk cartons

- Lead time by order size

- Return or remake rules for defects

This structure helps both sides. It also supports repeat orders.

How buyers can evaluate a Vietnam supplier efficiently

You do not need a long audit. You need repeatable signals.

Start with three actions:

- Request recent production photos and packing photos.

- Ask for a quick live video call walkthrough.

- Place a small test order with your core specs.

A real factory answers fast and shows real workflow. A reseller often delays visuals.

Final thoughts

Wholesale wavy hair extensions require careful sourcing. Buyers should verify wave stability, surface condition, and batch consistency. Factory control and clear quality checks reduce long-term risk.

Vietnam remains a strong sourcing option when buyers choose the right partners. At Lexhair Factory, these principles guide daily production for wholesale wavy hair extensions supplied from Vietnam.

Lexhair Factory | Contact Information & Hair Catalogue

WhatsApp

European-tone hair: (+84) 96 924 1128

Wavy/Curly hair/Raw hair: (+84) 97 809 1128

Instagram

Lexhair Factory’s Main Instagram

Lexhair Factory’s Wavy/Curly Raw Hair Instagram

Website

Lexhair Factory Vietnam